| Corfast Bulbtite rivets

|

|

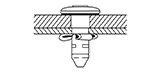

| Bulb-tite® rivets differ from standard blind rivets because they form

3 folded legs on the blind-side when upset.

The 3 legs provide a large blind-side footprint and high clamp load.

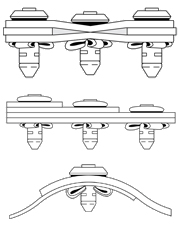

Bulb-tite® rivets are ideally suited for fastening soft or sensitive

materials. Large hole tolerance, variable material thickness and uneven surfaces are, in most applications, no problem for Bulb-tite®. Installed parts are vibration resistant and high strength. When fitted with neoprene washers Bulb-tite® rivets can be made air and watertight. Installing with a special nosepiece positively retains pins. Bulb-tite® rivets have been used for many years in the commercial vehicle, roofing, cladding and many other industries. |

|

|

Special features: • installed from one side - no access to blind-side required • simple installation - pin breaks flush or just below surface of head • positive retention of pin after installation • wide grip range - reduces parts inventory • corrosion resistant materials - aluminium and zinc passivated steel • vibration resistant through patented design • very low radial pressure applied to hole - does not damage surface finish of application material • versatility - can be used in flat or curved components • watertight when used with neoprene washer |

Hole tolerance: Correct installation is possible even if the holes are slightly offset (as long as the rivet can be inserted through both components).

Blind rivets: Can be installed in applications that may only be accessed from one side.

Break pin: Installation is complete when the mandrel breaks flush or just below the head.

Clamp load: Positive retention of the pin and the 3 blind-side folded legs provide a very high clamp load.